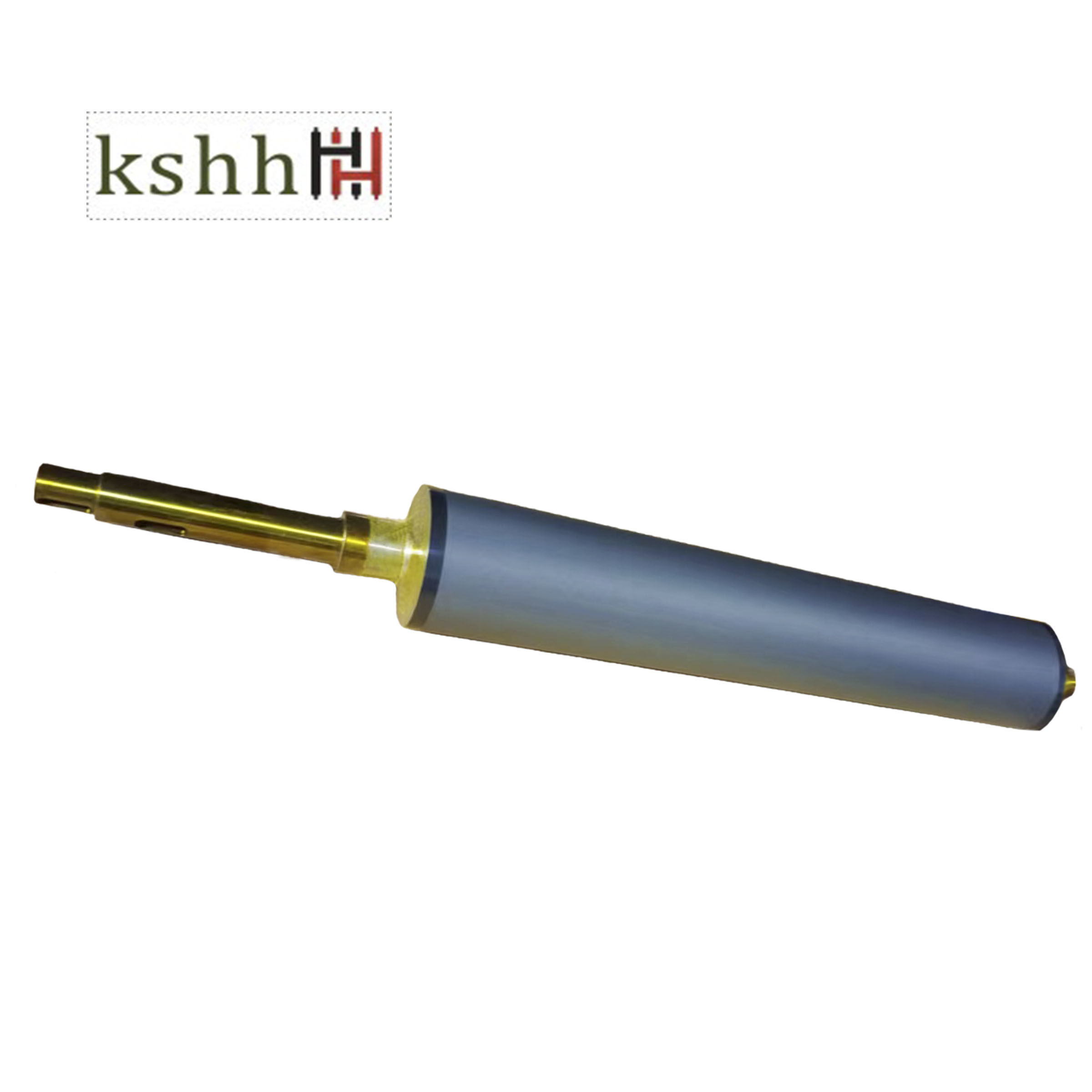

LQ-GII is the next generation sheet photopolymer specifically designed to address all direct print corrugated board requirements.

sheet photopolymer provides excellent solids coverage, while its low tack and high resilience offer long and clean press runs.

Features

• Especially for printing on coarse corrugated fluted board, with uncoated and half coated papers

• Ideal for retail packages with simple designs

• Optimized for use in inline corrugated print production

• Very good ink transfer with excellent area coverage and high solid density

• Perfect adaptation to corrugated board surfaces reduces washboard effect

• Less plate cleaning due to special surface properties

• Extremely robust and durable material thus

▫ high print run stability

▫ excellent storage capability

▫ low swelling characteristic

▫ high resistance to ozone

Technical Specifications

| Model | 284 | 318 | 394 | 470 | 500 | 550 | 635 | 700 |

| Thickness(mm) | 2.84 | 3.18 | 3.94 | 4.70 | 5.00 | 5.50 | 6.35 | 7.00 |

| Hardness (Shore Å) | 43 | 42 | 38 | 37 | 36 | 35 | 34 | 34 |

| Image reproduction | 3 - 95% 100 lpi | 3 - 95% 80 lpi | ||||||

| Minimum isolated line(mm) | 0.20 | 0.20 | 0.20 | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Minimum isolated dot(mm) | 0.30 | 0.30 | 0.30 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Max size (inch/mm) | 52×80/1320×2032 | |||||||

Recommended Processing Conditions

| Gauge (mil/mm) | Back exposure (seconds) | Main exposure (mins) | Wash out (mm/mins) | Dry (hours) | Detack (mins) | Post exposure (mins) |

| 2.84 | 40-60 | 8-15 | 140-160 | 1.5-2 | 8 | 5 |

| 3.18 | 40-60 | 8-15 | 140-160 | 1.5-2 | 8 | 5 |

| 3.94 | 60-80 | 8-15 | 140-160 | 2-2.5 | 8 | 5 |

| 4.70 | 40-60 | 8-18 | 140-160 | 2-2.5 | 8 | 5 |

| 5.00 | 40-60 | 8-18 | 140-160 | 3 | 8 | 5 |

| 5.50 | 90-110 | 8-18 | 140-160 | 3 | 8 | 5 |

| 6.35 | 90-110 | 8-18 | 140-160 | 3 | 8 | 5 |

| 7.00 | 95-115 | 8-18 | 140-160 | 3 | 8 | 5 |