Thermal Double Layer Offset UV Ink Printing CTP Plate

Model: ECOO-ED

1. Application

EcooGraphix Double Layer Therrmal CTP Plate can be used for long runs high grade commercial and newspaper printing. It can also be used for the UV ink printing with good performance.

2. Specification

| General Information | |

| Plate Model | ECOO-ED |

| Plate Type | Thermal UV-CTP Plate(Double Layer) |

| Application | High grade commercial and newspaper printing |

| Substrate | Electro chemically Grained and Anodized lithographic Aluminum |

| Aluminum alloy | Standard 1050 Alloy |

| Coating | Two-layer system, IR sensitive, positive acting |

| Gauge | 0.15, 0.20, 0.25, 0.30, 0.40 (mm) |

| Maximum short grain width | Maximum width 1280 mm |

| Plate intermix | Kodak Electra Excel HRL/HRO Thermal Plates, Kodak Sword Ultra Thermal Plates, Kodak Capricorn Excel Positive Plates, Kodak PP3 positive plates, Agfa Energy Elite, etc. |

| Length of Run | Ordinary Ink: 100,000 to 200,000 impressions UV Ink: 50,000 to 100,000 impressions |

| Exposing | |

| CTP Plate Making Machine Plate setters | Kodak: Trendsetter/Lotem/Magnus; Fuji: Javelin T9000HS Heidelberg: Top setter/Supra setter; Luscher: Xpose Plate setter Screen: PT-R, Creo: Scitex EcooGraphix Thermal CTP Tseries |

| Exposure energy | 110 - 130 mj/cm² |

| Spectral Sensitivity | 800-850 nm - Peaks 830nm |

| Resolution | 1-99% at 200 LPI |

| FM capability | 20 micron stochastic |

| Image color | Blue Green to Pale Green |

| Developing | |

| Processor | All the kind Brands |

| Developer | Kodak Gold Star or our own developer |

| Processing temperature | 23°C +/- 2°C |

| Developing time | 25 - 30 sec |

| Processing Speed | 0.80 - 1.20 m/min |

| Storage and handling | |

| Safelight | Daylight handling |

| Shelf Life | 12 months under recommended storage conditions |

| Packaging | Available in all standard formats, including bulk packaging options such as APL packaging |

| Storage and handling | Stored in a cool and dry environment, away from excessive cold, heat and humidity. |

3. Characteristic

Features

- Positive writing thermal plate

- Double layers system

- Made with high grade aluminum from Europe

- Wide adaptability for different plate setter brands

- Non-ablative coating

- Run lengths up to 100,000 impressions

- UV Ink up to 50,000 impressions

- Ability to print both AM and FM screening

Advantages

- Resist UV-ink; workable with both normal ink and UV ink

- Mature product, good stability and wide processing latitude

- Long run length with non-ablative coating

- Being adaptive to most of platesetters, processors and solutions

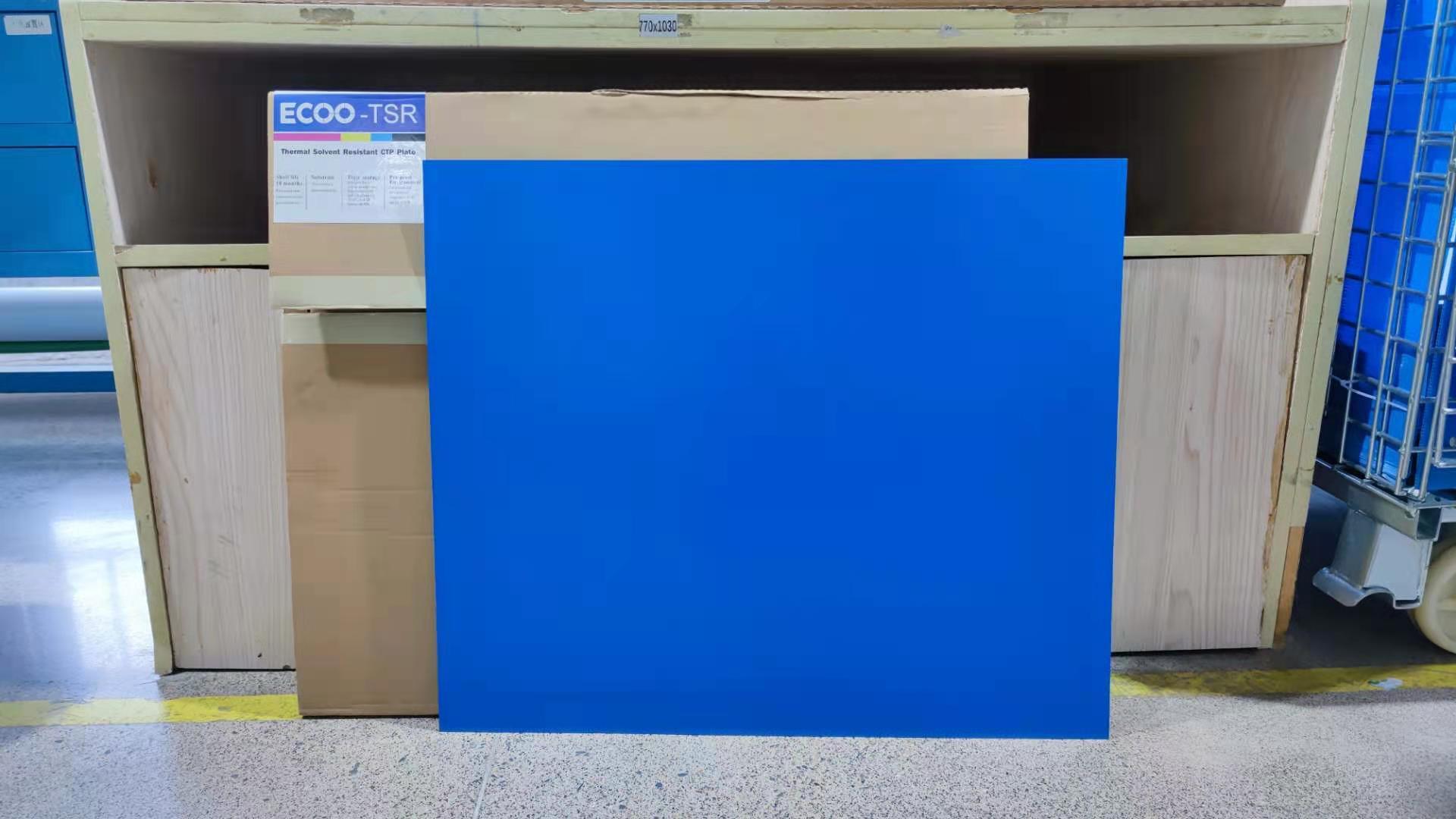

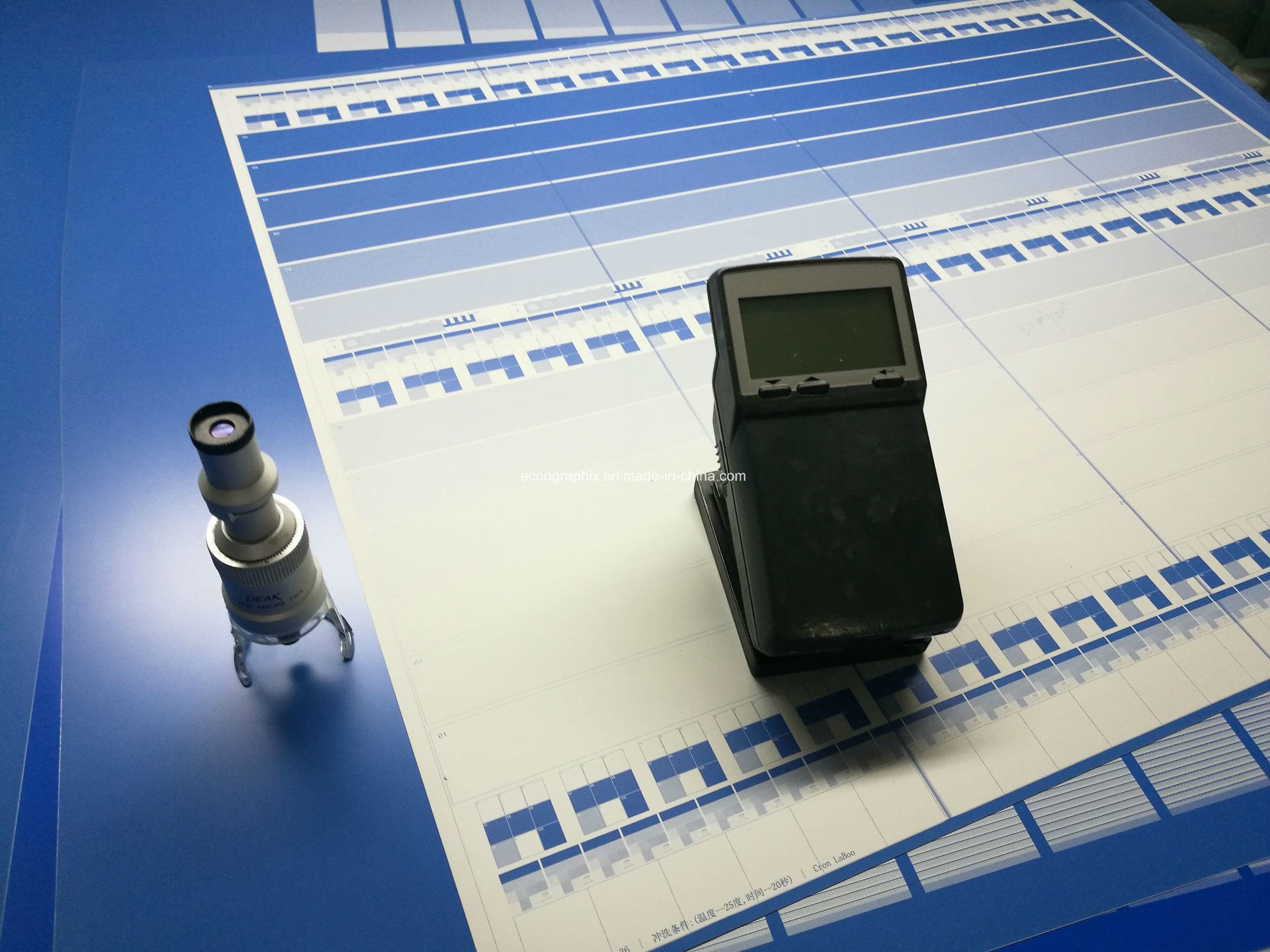

4. Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

5. Certification

6. FAQ

Q1: Can I get the sample ?

A: We are very glad to provide some sample for you to test. We usually provide 5-15 pieces plates for free, but sincerely hope to get your kind support for the air courier freight. This cost can be returned to you in your first order.

Q2: What is the cost for the CTP plate sample freight ?

A: The air freight depends on the packing size and weight, and the delivery destination. Or you can arrange the Pick-up service from your local agent.

Q3: How long can the sample be ready ?

A: It usually takes about 3 days to prepare the sample.

Q4: Can I visit your factory ?

A: You are warmly welcome to visit our factory! Our company is in Hangzhou city, which is about 1.5 hours by train from Shanghai.

Q5: How many Square Meters CTP plates can feed one 20' container ?

A: About 20000-25000SQM.

Q6: Can I take my own brand and label on the packing ?

A: Yes, we can provide the OEM with the customer's brand and label.