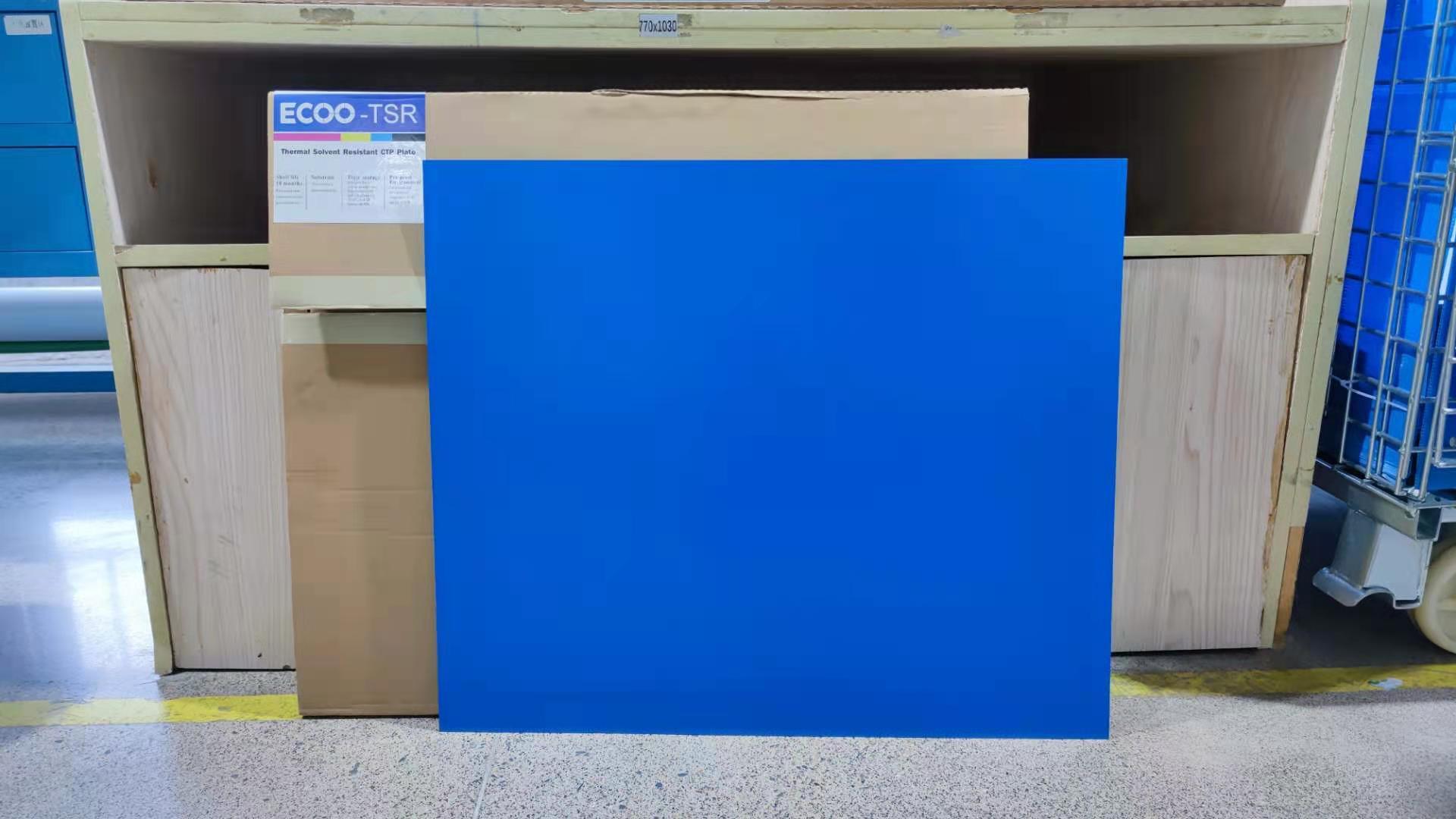

Violet Plate High Quality Aluminum Plate For Offset Printing

Model: ECOO-V

Application

EcooGraphix Low-chemical Violet CTP Plate ECOO-V can be used for newspaper printing. It is an environmental friendly product. Compared with normal Violet CTP plate, ECOO-V keeps original photosensitive features and printing compatibility.

Specification

| Model | ECOO-V |

| Plate Type | Low chemistry violet plate, negative printing |

| Application | Newspaper Printing |

| Substrate | Electro Chemically Grained and Anodized Aluminum |

| Gauge | 0.20, 0.25, 0.30, 0.40(mm) |

| Maximum short grain width | Maximum width 1320 mm |

| Developer | Developing gum |

| Length of Run | Unbaked: 200,000 impressions; Baked: 500,000 impressions(dependent upon image resolution, press, press chemical, ink and paper conditions) |

| Plate setters Capability | All the main brands violet CTP in market, laser power no less than 30 mw |

| Aluminum | Standard 1050 Alloy |

| Exposure energy | 50-60 μj/ cm²(based on plate setter and developing condition) |

| Developing time | 20±3 sec |

| Developing Temperature | 28±2 ºC |

| Spectral Sensitivity | 405 nm |

| Resolution | 150lpi(2-98%), under 1800dpi, 25μm line can be produced. |

| Preheat | 95-121 ºC |

| Brush Speed | 100 rpm |

| Shelf life | 12 months under recommended storage conditions |

| Storage and handling | Store plates flat in their packaging, away from excessive cold, heat or high humidity; Recommended condition is: temperature 15-28ºC and RH between 30-70%; Handle with care, the maximum height is 1.2m'; Open the box under yellow light. Sealed the box with remained plate to avoid moisture. |

Plate Type Low chemistry violet plate, negative printing

Application Newspaper Printing

Substrate Electro chemically Grained and Anodized Aluminum

Gauge 0.20, 0.25, 0.30, 0.40(mm)

Maximum short grain width Maximum width 1320 mm

Developer Developing gum

Length of Run

Unbaked: 200,000 impressions;

Baked: 500,000 impressions(dependent upon image resolution, press, press chemical, ink and paper conditions)

Plate setters Capability All the main brands violet CTP in market, laser power no less than 30 mw

Aluminum Standard 1050 Alloy

Exposure energy 50-60 μj/ cm² (based on plate setter and developing condition)

Developing time 20±3 sec

Developing Temperature 28±2 ºC

Spectral Sensitivity 405 nm

Resolution 150lpi(2-98%), under 1800dpi, 25μm line can be produced.

Preheat 95-121 ºC

Brush Speed 100 rpm

Shelf life 12 months under recommended storage conditions

Storage and handling

Store plates flat in their packaging, away from excessive cold, heat or high humidity;

Recommended condition is: temperature 15-28ºC and RH between 30-70%;

Handle with care, the maximum height is 1.2m';

Open the box under yellow light. Sealed the box with remained plate to avoid moisture.

Features

♥ Simplifying the processing, only 3 steps including preheating, developing, and drying.

♣ Reducing chemical consuption, saving water.

♦ Weak alkali developer maximumly avoid developing inconsistency due to exhausted developer. It makes print wuality more stable.

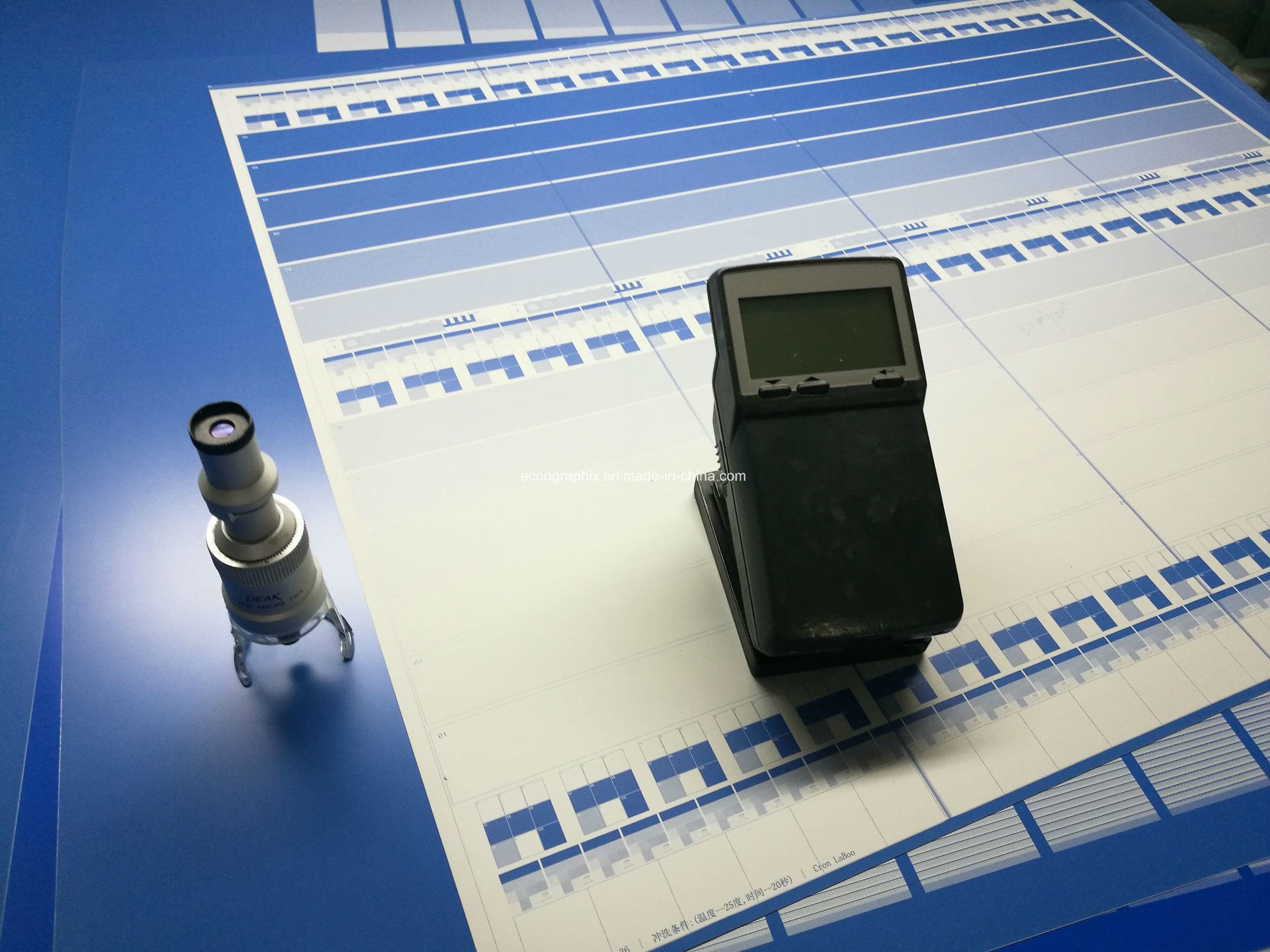

Producing and Packing

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

Certifications

Q1: Can I get the sample ?

A: We are very glad to provide some sample for you to test. We usually provide 5-15 pieces plates for free, but sincerely hope to get your kind support for the air courier freight. This cost can be returned to you in your first order.

Q2: What is the cost for the CTP plate sample freight ?

A: The air freight depends on the packing size and weight, and the delivery destination. Or you can arrange the pick-up service from your local agent.

Q3: How long can the sample be ready ?

A: It usually takes about 3 days to prepare the sample.

Q4: Can I visit your factory ?

A: You are warmly welcome to visit our factory! Our company is in Hangzhou city, which is about 1.5 hours by train from Shanghai.

Q5: How many square meters CTP plates can feed one 20' container ?

A: About 20000-25000SQM.

Q6: Can I take my own brand and label on the packing ?

A: Yes, we can provide the OEM with the customer's brand and label.