ECOO-G thermal DOP plate (develop on press ), could be applied onto press machine directly without processing/developer after imaging, chemistry free, environment-friendly, as same as Sonora XP.

ECOO-G is well sold in Europe, USA, Canada. It is like Kodak Sonora and Agfa Azura. It meets the trend of being environment-friendly and has bright future. This plate can be applied on printing machine directly without processing and developing. So it saves cost of labor, water treatment and developer tank. Hope you like it.

Product Parameters

| Model | Ecoo-G |

| Plate type | Non-ablation thermal-Negative type |

| Application | High grage commercial and newsprinting |

| Substrate | Electrolyte graining and Anodozed AL substrate |

| Thickness | 0.15mm-0.4mm |

| Spetrum scope | 800-850 nm |

| Plate setter | Various dominant thermal platesetters in the market |

| Low-energy imaging | 130-150 mj/m² |

| The period of latent image stablization | ≤7 days |

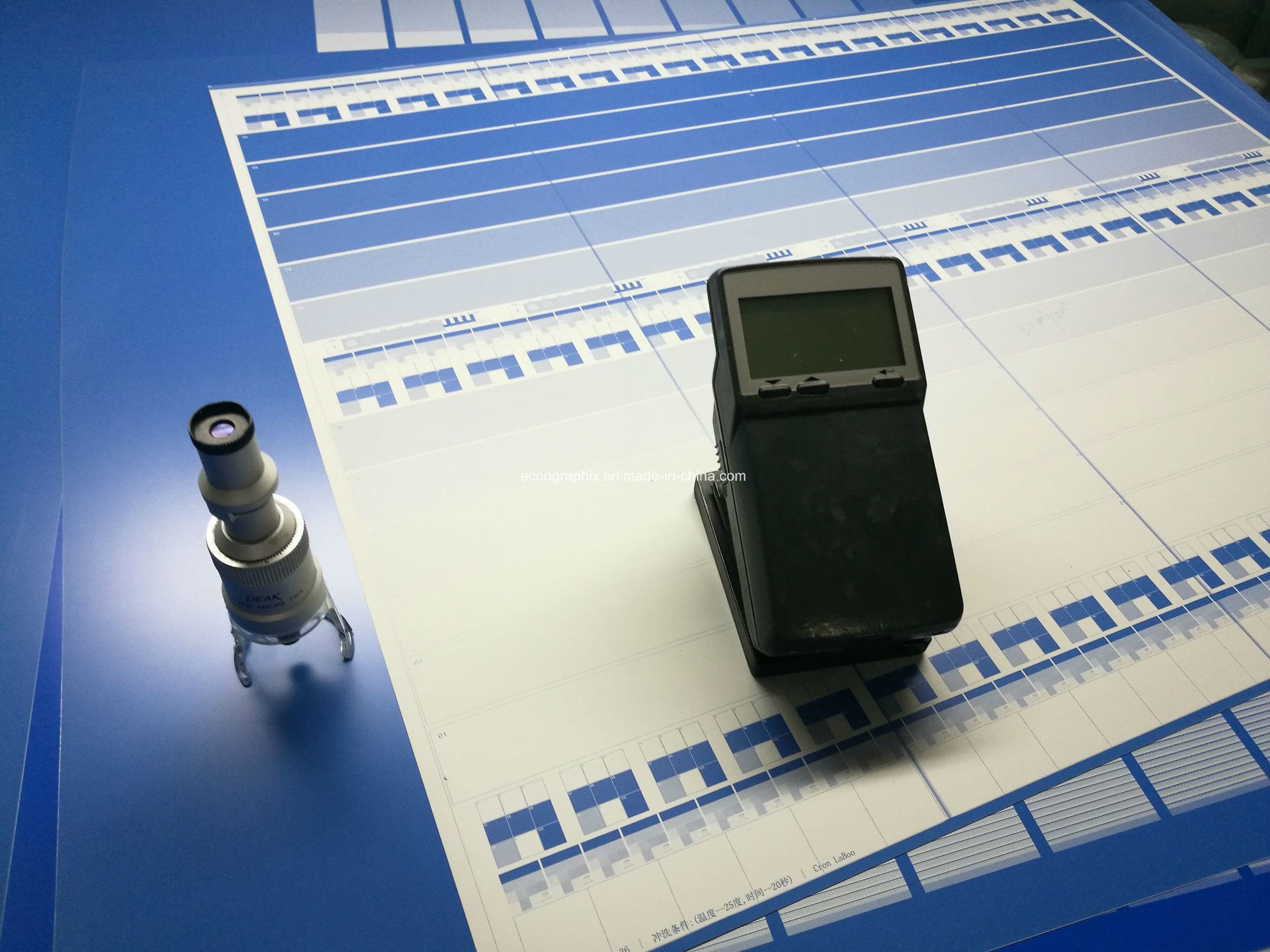

| Recommended screen method | 1-99@ 200 lpi AM/20U FM and mixture |

| The paper number of start-up | < 50 sheets |

| Safety light | 1 hour under fluorescent lamp, no direct irradiation with natural light, 4 hours under yellow light. |

| Processing | Without processing, directly on press |

| Run length | 100000 impressions, actual run length depend on printing conditions |

| Baking | No recomended |

Features

High-quality aluminum substrate and unique-grain processing technology. The substrate grain is uniform fine, which ensures the exact dot reproduction and excellent printing adaptability of the printing plate.

The professional formula design with infrared laser sensitive phase- change layer ensures that the plate can be put on press directly after exposure.

High sensitivity , wide tolerance, screen dots with margin sharpness

Excellent printability, fast-inking balance, suitable for high-grade commercial and packaging printing.

Compatible with various dominant thermal platesetters in the market, suitable for manual and automatic loading system.

Bright room operation in which people can operate safely under fluorescent lamp.

Stable quality.

A variety of the plates provided with thickness from 0.15mm to 0.40mm.

Application

Suitable for sheet-fed offset press or high speed rotary offset press.

Run length: 100000 impressions

Suitable for different types of traditional inks and fountain solutions, including alcohol's substitutes as fountain solutions.

Unsuitable to improve run length by baking plates.

Processless plate V.S normal process plate

| ECOO-G | V.S | ECOO-ED/ECOO-ES |

| (Thermal Negative Processless plate ) | (Thermal positive process plate) | |

| No processor requires, save your cost on processor machine | A processor machine required | |

| No chemistry to deal with, save your cost on developer and water treatment | Developer required | |

| Elimination of processing time, more time available for other work | 30 seconds in processor per sheet | |

| Same performance level as Azura & Sonora, but more competitive price | / | |

| Environment-friendly product, has bright future, policy support | Need extra water treatment device and space to treat wasted developer | |

| Higher price than normal process plate | More economic in price, lower business cost | |

| 20 pcs of starting papers until image come out | less waste in starting paper | |

| Not strong contrast between imaging zone and non-image zone, not easily to recognize image mistake before printing | Strong contrast after imaging is helpful to observe image mistake |

Plate making procedure

| CTP model Data | Kodak trendsetters | LOTTEM 400(TH1.7) | MAGNUS 400 | Screen 8600S |

| Laser power | 15-17W | 300-320mw | 19.5-21.5W | 80-90 % |

| Drum speed | 250-300rpm | 850-900rpm | 400-450rpm | 800-900rpm |

| Resolution | Customized | Customized | Customized | Customized |

| Parameter that need set up | Focus/ Zoom | Focus/ Zoom | Focus/ Zoom | Focus/ Zoom |

1. How long is the lead time?

The lead time is normally 45 days.

2. Do you offer free plate samples?

Yes, we offer free testing samples maximum 12 pcs for each size but with delivery fee to collect.

3. How do you guarantee stable quality?

There are 3 inpecting procedures: 1, automatic on-line 24h scanning detector; 2, random sampling per 15 mins at the producing line; 3, manually full inspection before packing. The production is mature. It is not a new product to us.

4. Do you have accompanying plate making products to enable one-stand easy purchase for some end users?

Yes. CTP machine, processors, violet plate, CTP-CTCP plate, chemistry(fountain solution, roller wash, etc.) are all available to make your purchase more easily.

5. Payment term?

Normally, 30% deposit, 70% before shipping, or LC at sight.

6. Is refrigerating container necessary for shipment?

No. The plate is relatively stable and mature. So normal container is enough unless some ertreme hot situations.

7. How to use this processless plate?

- Clean all the inks on the blanket;

- Start the press machine, apply the water roller, run 15-20seconds;

- Apply the ink rollers 20-30 seconds;

- Apply the paper and start print.