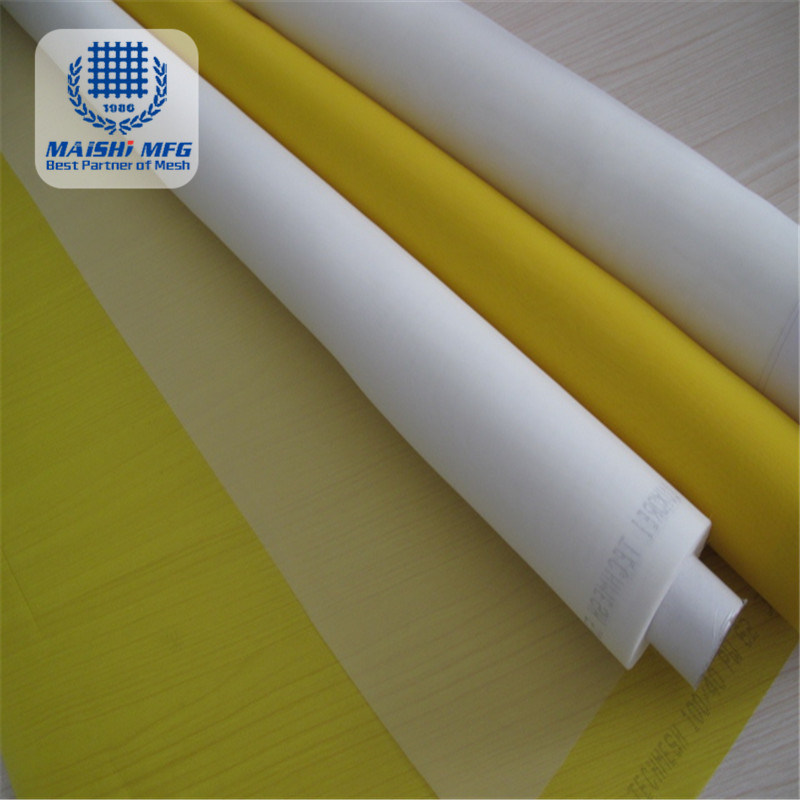

1> 100% polyester monofilament

2> Excellent tear resistance

3> Excellent dimensional stability

4> Higher tension strength & break point

5> Low elongation

Advantage:

Faster tension without damage to the threads

Improved fabric strength

Faster tension stabilization

Higher tension threshold and breaking point

Less tension loss during the stretching process

Faster turnaround time from the screen room to the press-room

Improved registration due to stable tension

Faster Print Speeds

1. Normal specifications

| Maishi Monofilament Polyester Printing Mesh (Bolting Cloth) | ||||||

| model | mesh count | APERTURE | THREAD DIAMETER | OPENING | thickness | INK THROUGH VOLUME THEORETICALLY |

| mesh/inch | micron | micron | % | micron | cm 3 /m 2 | |

| 6-400 | 15 | 1300 | 400 | 65 | 780-810 | 560 |

| 10-250 | 25 | 700 | 250 | 49 | 508-518 | 355 |

| 12-250 | 30 | 610 | 250 | 53 | 495-505 | 305 |

| 15-250 | 38 | 467 | 250 | 49 | 489-501 | 213 |

| 18-150 | 45 | 410 | 150 | 53 | 255-275 | 138 |

| 21-150 | 55 | 330 | 150 | 46 | 260-280 | 123 |

| 24-100 | 60 | 316 | 100 | 57 | 136-145 | 109 |

| 24-120 | 60 | 302 | 120 | 51 | 230-240 | 104 |

| 30-120 | 75 | 213 | 120 | 41 | 235-345 | 102 |

| 32-100 | 80 | 212 | 100 | 46 | 145-155 | 69 |

| 36-90 | 90 | 183 | 90 | 44 | 160-165 | 65 |

| 39-55 | 100 | 195 | 55 | 56 | 88-96 | 55.0 |

| 39-80 | 100 | 166 | 80 | 43 | 125-130 | 59.0 |

| 43-80 | 110 | 147 | 80 | 40.8 | 127-132 | 53 |

| 48-70 | 120 | 135 | 70 | 41 | 108-120 | 45.5 |

| 54-55 | 135 | 118 | 55 | 47 | 88-96 | 44.5 |

| 54-64 | 135 | 115 | 64 | 38.5 | 95-105 | 38.9 |

| 54-70 | 135 | 108 | 70 | 34 | 108-120 | 40 |

| 58-55 | 145 | 118 | 55 | 38 | 89-94 | 39.5 |

| 61-64 | 155 | 105 | 64 | 42 | 98-107 | 33 |

| 64-45 | 160 | 105 | 48 | 43 | 73-82 | 36.5 |

| 64-55 | 160 | 98 | 55 | 38 | 85-95 | 36.1 |

| 64-64 | 160 | 88 | 64 | 30 | 95-105 | 30.7 |

| 68-55 | 175 | 85 | 55 | 34 | 85-90 | 29 |

| 72-48 | 180 | 90 | 48 | 36 | 75-84 | 33.1 |

| 77-55 | 190 | 81 | 55 | 30 | 88-97 | 26.6 |

| 80-45 | 200 | 75 | 45 | 36 | 65-74 | 27.7 |

| 80-48 | 200 | 72 | 48 | 33 | 75-84 | 28.7 |

| 90-48 | 230 | 56 | 48 | 25 | 77-85 | 23.5 |

| 100-40 | 250 | 58 | 40 | 33 | 62-71 | 21.3 |

| 110-40 | 280 | 48 | 40 | 27 | 65-71 | 18.4 |

| 110-34 | 280 | 54 | 34 | 35.5 | 52-57 | 20.2 |

| 120-34 | 305 | 45 | 34 | 30.5 | 52-57 | 18.4 |

| 140-34 | 355 | 31 | 34 | 19.5 | 56-62 | 14.4 |

| 150-31 | 380 | 36 | 31 | 29 | 43-47 | 13.1 |

| 150-34 | 380 | 30 | 34 | 20.5 | 56-62 | 14.9 |

| 165-31 | 420 | 31 | 31 | 23 | 52-58 | 12.88 |

D (DENIER) =MICRON 9D=31MICRON, 12D=34MICRON, 16D=40MICRON, 22D=48MICRON, 30D=55MICRON; 40D=64MICRON, 50D=70MICRON, 60D=80MICRON, 80D=90MICRON, 100D=100MICRON Notice: Other abnormal specification can be produced if the quantity more than 3000sqm | ||||||

2. Production process

Material yarn from Jintong, Switzerland and Japan, we inspect those yarn arrived (tolerance, tensile strength, physics test etc.).

During production, first we put the warp wires on the beam, drawing the warp wires into heddle and reed. Then our experienced weaver will start weaving mesh according to orders.

Initial survey is taken during and after weaving. Then the heat setting treatment and physical properties inspection will be done before we get tentative finished rolls (normally 60-500 meters rolls).

In the end, after the final inspection, we will cut the mesh into small rolls (20m-50m) according to customer orders.

3. Mesh Test

MAISHI test the mesh before the goods dispatched from our factory to ensure their quality.Make sure customers get 100% polyester mesh.

Testing include:

1> Mesh count inspect

2> Thickness inspect

3> Thread dia & hole inspect

4> Elongation test

5> Tensile test

Detailed Image

4. Packing

We have two kind of packing type:

1.Fold the mesh into plastic bag ,then in carton.Suitable for small quantity and have no requirement on the crease.

2.Pack the mesh with paper and plastic bag,then in carton.Suitable for large quantity and the mesh has better surface then folding type.

Folding packing

Rolling packing

Paper carton package

Outside pack with weater-proof weaving cloth

5. Application

100% polyester mesh are widely used for textile printing, ceramics printing, glass printing, electronics printing, CDs printing, high-density printed circuit board printing.

1> Ceramic printing / Glaze printing

2> Garment Printing

3> Glass printing

4> PCB printing

And other applications include:

CD/DVD Printing,

Ceramic Decorating,

Graphic Screen Printing (Glass Containers, Labels,Large Format UV Graphic, Small Format UV Graphic, Solvent Graphics, Tubes and Cartridges),

Package Printing,

Printed Electronics,

Printing on Glass,

Solar Cell Printing,

Textile Printing,

Tableware.

6. Our Company

Maishi is one of the top manufacturers and exporters of screen printing mesh.Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology.

· Dedicated and experienced weavers.

· Consistent quality products.

· On-time delivery.

· We have 15 R&D technical staffs,with more than 10 years experience.

· 80% repeat customers.

· Reasonable claim refund system.

Mainly market : Our mesh sells good all around the world. Such as: North America (USA, Canada, Mexico), South America( Braizil, Chile, Argentina, Peru etc.), European country (Germany, France, Italy,Poland, etc.), Asia (UAE, Iraq, Iran, Thailand, Vietnam , Malaysia, Turkey, Pakistan, Bangladesh etc. )

7. Delivery time & Payment:

Delivery time

Usually we can ship the goods within 5-15days as we have stocks 500-2000m for different mesh count.

The exact order quantity will be checked according to our production status.

Payment

1) 100%T/T in advance if order amount less than USD10000.00

2) 30% paid in advance and 70% balance paid before shipment if order amount more than USD10000.00.

3) Irrevocable L/C at sight.

Any other payment term can be negotiatory.

If you need 100% polyester mesh, please contact us and let us know your specifications, include:

1. Material

2. Mesh count

3. Wire diameter or hole size

4. Mesh color

5. Roll size

6. If you can tell your application, it will be much helpful

7. Quantity

Welcome to your inquiry.